Think the future of “clothing”, from Scientific point of view.

Home > Equipment

The biggest feature is Senko Yoshida, and staining plant.

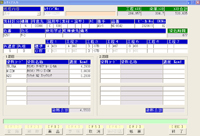

The soft yarn is wound, spindle Once you have filled in their work, based on the automatic crane production planning, dyeing machines, yarn put into the dryer, do the retrieval.

Automated staining machine, water pressure, pump power control, temperature control, and automatically performs all steps involved in the staining power of the drug and timing of infection.

If one administrator, can operate 24 hours a day in the dyeing machine bed 38.

This equipment has made it possible departure from the work environment was said to 3K.

| Dyeing machine | 250kg | 6 |

|---|---|---|

| 200kg | 4 | |

| 150kg | 4 | |

| 80kg | 8 | |

| 35kg | 4 | |

| 24kg | 3 | |

| 12kg | 5 | |

| 6kg | 4 (6 km from the minimum lot) | |

| High pressure dryer | 250kg | 2 |

| 200kg | 2 | |

| 80kg | 4 | |

| 12kg * 2 | 1 | |

| 12kg | 2 |

Dyes and chemicals are injected into the perfect pot was stored in a tank at the time once ready.

The device automatically measure the liquid dye.

Some liquid dye system to automatically dissolve the dye powder.

Some liquid dye system to automatically dissolve the dye powder.

To dissolve the dye can not be saved, the weight of the powder remains.

Based on production planning, and retrieve the required automatic warehouse dyes.

Deshimasu weighing the manpower, do not weigh the error and the balance is connected to the computer.

And feedback data is stored in the stained variety.

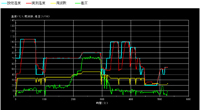

Screen, you can see the behavior when dyed or printed out.

Establishment of dyeing method to help solve the problem of new materials and process efficiency.

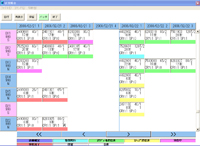

Pot will be allocated automatically according to the order entered.

Make sure to confirm the appointment by the administrator.

Computer will automatically advance the process based on production plan has been finalized.

Once data has been dyed your computer has been numbered.

If you specify the materials and colors and numbers, automatically calculated according to the volume usage Resaipu is called immediately.

The prepared liquid dye machine for beaker.

Excellent reproducibility in the production of measuring instruments so dyeing machine and the same principle.

The beaker machine to accommodate a wide variety and short delivery time.

Each pod is x24, you can create a variety of materials simultaneously beakers are individually temperature controlled.

Dyeing is what you use a lot of heat and water, I try to be conscious of the full environment.

Voluntary domestic emissions trading scheme to the Ministry of Competition (Phase II) is participating in the.

Liquefied natural gas boilers with a small reflux

LNG Satellite Facilities

Introduced to reduce emissions of CO2.

For areas without natural gas pipelines, liquefied natural gas were transported in a trailer (-167 ℃), and has been used to vaporize on the premises and stored in a special pressure tank. (The use of heat to vaporize the waste gas).

In conjunction with natural gas energy, a small (one 2.5t × 5) introducing a reflux boiler.

If necessary, it will automatically switch the unit used, the gas can be used efficiently.

Sedimentation of activated sludge wastewater treatment plant system

After dyeing wastewater with groundwater pumped up, and to clean pit can be discharged into the river level.

pH, transparency, standards and processes Setouchi the COD, BOD.

Waste heat is removed by heat exchangers used in hot water to make hot water for dyeing.

Dyeing machine and winder motor has minimal power requirements are all controlled by an inverter.